The industrial automation landscape is undergoing a massive transformation. As factories evolve into smart, interconnected ecosystems, the need for reliable, scalable, and intelligent embedded computing is at an all-time high. System on Modules (SoMs) are becoming the cornerstone of this evolution—bridging the gap between rapid development and industrial-grade performance.

In this blog, we explore how SoMs bring unmatched value to industrial automation applications—from PLCs and motor controllers to HMI panels and edge gateways.

What is a System on Module?

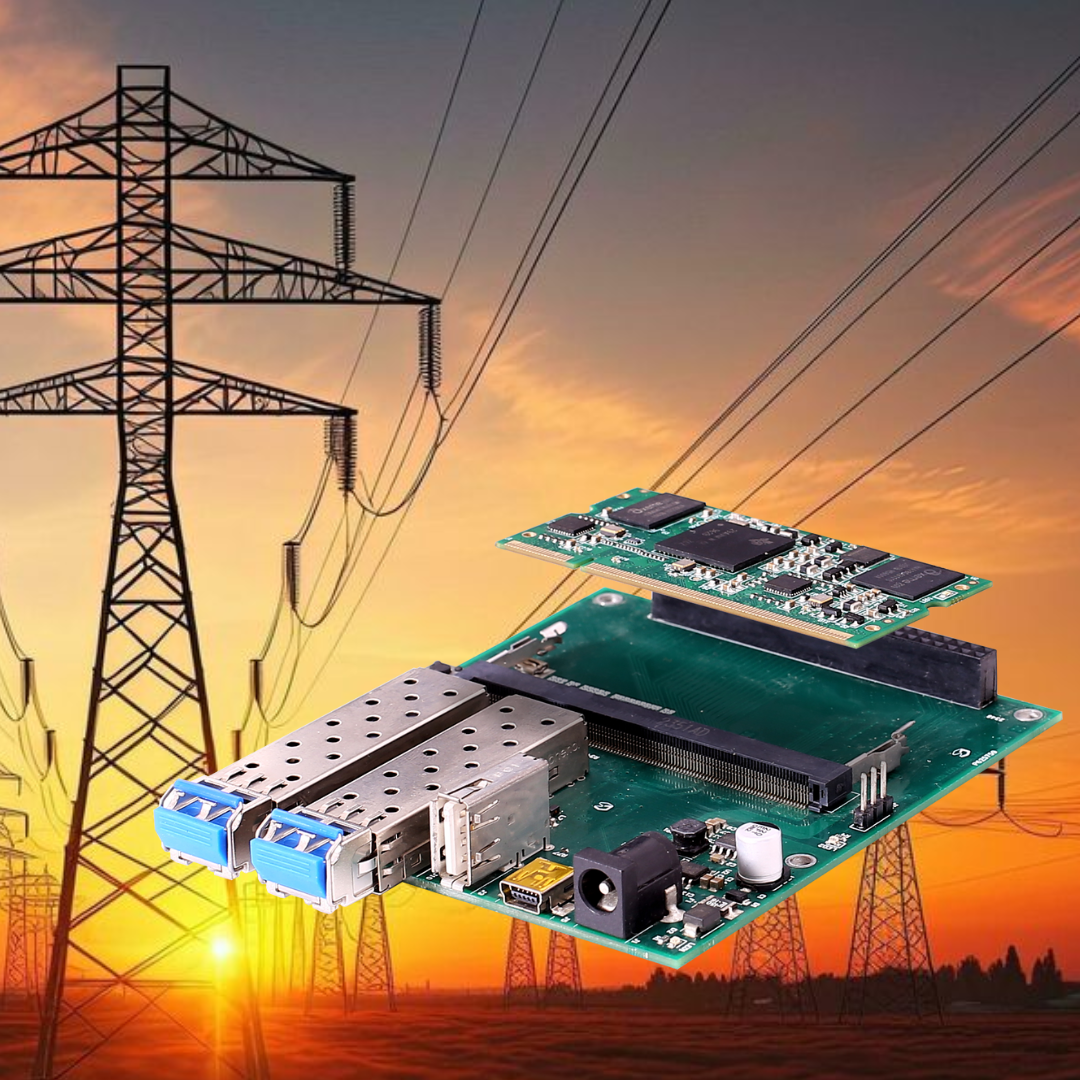

A System on Module (SoM) is a compact embedded computing unit that integrates the processor, memory, power management, and essential I/O into a single, ready-to-deploy module. These modules are mounted on a custom carrier board that houses application-specific interfaces and connectors.

In essence, SoMs offer the computing core of your industrial product—without the burden of full board design or low-level hardware complexity.

Key Advantages of SoMs in Industrial Automation

1. Faster Time to Market

Industrial applications often have tight development timelines. SoMs eliminate the need for custom processor board design, allowing engineers to:

Focus on application-specific carrier boards

Begin firmware and UI development in parallel

Reduce prototype-to-production cycles by months

2. Rugged and Reliable Performance

Industrial environments demand robustness. SoMs are designed with:

Extended temperature ranges (typically -40°C to +85°C)

Long lifecycle components

Proven reliability in high-EMI and harsh electrical conditions

This makes them ideal for applications like motor control, process monitoring, and factory automation.

3. Scalability Across Product Lines

With SoMs, you can create a scalable product portfolio by:

Using a common carrier board with interchangeable SoMs (e.g., from Cortex-A7 to Cortex-A53)

Offering low, mid, and high-end variants with the same hardware architecture

Future-proofing designs with upgrade paths to newer SoMs without complete redesign

4. Industrial Protocol Support

Modern SoMs come with native or expandable support for key industrial protocols:

EtherCAT, PROFINET, Modbus, CAN, RS-485, and more

PRU (Programmable Real-time Units) support in some processors (like AM335x) for real-time protocol handling

Multiple UARTs, SPI, I2C interfaces for flexible sensor and actuator connectivity

5. Reduced Development Risk

Designing a processor board from scratch involves:

Complex signal integrity, DDR routing, PMIC integration

EMI/EMC considerations

Extensive validation and testing

SoMs abstract all this by offering a pre-validated computing module, reducing risk and simplifying certification for industrial use.

6. Long-Term Availability

Industrial equipment often requires 10+ years of availability. SoM vendors typically:

Commit to long lifecycles (10–15 years)

Offer stable supply chains

Provide roadmap support for seamless migration

This ensures your automation products remain viable and serviceable for years.

7. Field Upgradeability and Maintenance

With flash-based storage and accessible bootloaders, SoM-based systems can be:

Remotely updated via secure OTA mechanisms

Serviced easily by replacing carrier boards while retaining the compute module

Diagnosed in the field using built-in debug and diagnostic interfaces

8. Cost Optimization at Scale

Though SoMs may seem costlier than custom boards at low volumes, they:

Reduce upfront engineering effort

Avoid costly design errors

Offer competitive pricing at scale

Enable shared use across multiple products

Over the product lifecycle, SoMs often result in significant cost savings.

Where Are SoMs Used in Industrial Automation?

Programmable Logic Controllers (PLCs)

Human Machine Interfaces (HMIs)

Motor Drives and Inverters

Industrial Gateways

SCADA Edge Nodes

Sensor Hubs and DAQ Systems

Closing Thoughts

System on Modules are enabling a new era of rapid innovation in industrial automation. By combining robustness, flexibility, and scalability, they allow OEMs and industrial product developers to focus on what matters most—delivering value through intelligent, reliable, and future-ready systems.

If you’re designing your next industrial product, it’s time to explore how SoMs can give you a head start.

Recent Comments

Latest Post

-

0 Comments

0 CommentsIoT Gateway M1

-

0 Comments

0 CommentsTouchWave

-

0 Comments

0 Commentsi.MX8MPLUS SBC NOVA